Improve Product Consistency In Industrial Baking

In the world of baking, efficiency and precision are key ingredients for achieving the perfect bake. As industrial bakeries look to meet the high standards of quality and consistency demanded by customers, the need for advanced spray technology in bakeries becomes increasingly apparent. Precision Spray Control (PSC) provides bakeries with the ability to enhance both aesthetics and functional aspects like pan oiling, mold inhibitors, or egg wash. By integrating PSC technology, bakeries can operate more efficiently, minimize waste, ensure that every bakery product is consistent and reflects your company's dedication to perfection.

1

Aug 24

Understanding Precision Spray Control

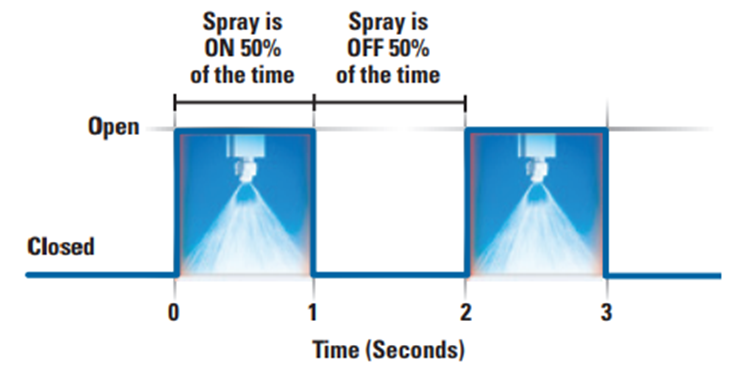

Precision Spray Control (PSC) is technology that gives you the ability to deliver the right amount of material to the right place at the right time. This system is particularly valuable in baking, where uniformity and efficiency are critical. By utilizing automated bakery spray nozzles, such as PulsaJet® nozzles, and real-time feedback mechanisms, PSC adjusts to variations in product line speeds. This ensures that each product receives the optimal amount of coating. This feedback comes from various sensors monitoring aspects like conveyor speed and product presence. The technology is both advanced and user-friendly, allowing bakeries to achieve the same result every time.

Key Benefits of PSC

- Real-Time Feedback: As previously mentioned, PSC employs real-time feedback mechanisms that continuously monitor various parameters, such as conveyor speed and product presence. This constant monitoring allows the system to make micro-adjustments on the fly, maintaining uniform coverage and ensuring that each product is sprayed correctly.

- Flow Rate Adjustment: One of the standout features of PSC is the ability to adjust the flow rate of the spray in real time. Whether bakery production lines speed up or slow down, PSC can automatically increase or decrease the amount of sprayed material to maintain a consistent application rate. This adaptability is crucial for achieving uniform coverage.

- Handling Different Materials: The versatility of PSC extends to handling a wide range of materials, from thin liquids like release agents to more viscous substances like chocolate. This is achieved through precise pressure control, heated systems, and nozzle design, allowing bakeries to use one system for multiple applications. Whether you need an egg wash sprayer or a pan lubricating nozzle, PSC can accommodate your needs seamlessly.

Results In Bakeries

Consistency Across Products

PSC improves consistency of coating applications by automatically adjusting to variations in line speed, bakeries can maintain uniform coverage regardless of production speeds. Furthermore, PSC can operate at different flow rates, accommodating a variety of products and coatings with ease. This versatility ensures that each item receives the perfect amount of coating every time. Eliminating variability inherent in manual spraying helps meet the high standards customers expect. To read more about how one bakery achieved uniformity in product quality through a system using PSC, click here to read the case study.

Waste Reduction and Efficiency

One of the most significant advantages of PSC is the capacity to reduce product scrap. By precisely controlling the application of coatings, bakeries experience fewer issues related to under or over-application. This precision enhances the consistency of bakery products and greatly cuts down on waste, leading to more efficient production processes and tangible savings. For instance, a bakery documented that it reduced scrap by 40% thanks to an automated spray system that utilized PSC. To read more about this specific case study, click here.

An additional way our systems reduce waste is detecting and reacting to empty pockets on conveyor belts. The system automatically adjusts to avoid unnecessary spraying in the absence of product. This feature is particularly beneficial in high-volume bakeries, where small inefficiencies can lead to substantial resource wastage.

Cost Savings

A notable benefit of PSC is the achievement of low flow rates without relying on air atomizing nozzles. The use of hydraulic PulsaJet nozzles eliminates the need for compressed air, which is a considerable saving given the high operational costs associated with compressors. Additionally, this approach reduces misting, a common issue that leads to maintenance challenges and extended cleanup times, further saving on operational or maintenance costs.

Enhanced Safety

Implementing PSC also enhances workplace safety. The reduction in misting decreases the risk of slippery surfaces which lowers the chances of slips and falls in the production area. Moreover, by minimizing airborne particles, PSC helps create a healthier work environment, as inhaling these mists can pose health risks to employees. This focus on safety not only protects workers but also aligns with best practices for workplace health. To read more about a company that increased their worker safety click here.

Conclusion

PSC is revolutionizing the baking industry by enhancing efficiency, consistency, and safety in production processes. As we've discussed, PSC ensures uniform application of coatings, such as egg was and chocolate glaze, resulting in high quality products every time. This advanced technology minimizes waste, optimizes ingredient usage, and adapts to production conditions, making it suitable for multiple applications within a bakery.

At Spraying Systems Co., we are committed to helping bakeries achieve excellence with our innovative spray technology. If you are ready to take your bakery to the next level with PSC, contact us today. Let us help you implement PSC and experience the difference in efficiency, quality, and sustainability.