Why Is Nozzle Maintenance Important?

Maintaining your industrial spray nozzles is crucial for ensuring optimal performance and longevity in industrial applications. Proper nozzle maintenance enhances efficiency and reduces costs by preventing premature wear and tear. Here we will explore essential nozzle maintenance practices, including nozzle cleaning tips and some common issues with nozzles. We aim to provide practical insights to help you maintain your spray nozzles effectively, ensuring they operate at their best for as long as possible.

27

Jun 24

Why is Nozzle Maintenance Important?

Regular nozzle maintenance is vital for consistent spray patterns and achieving desired results. Minor wear or damage to a spray nozzle orifice may not seem like a serious issue, but this alteration can affect spray pattern uniformity and lead to thousands of gallons of water or chemicals wasted annually. The result could be reduced product quality and increased operating costs. Poorly maintained nozzles can lead to inefficiencies, increased operational costs, and potential damage to the spray system. For a basic overview of nozzle optimization, click here to read more.

How Do Worn Nozzles Affect Performance and Efficiency?

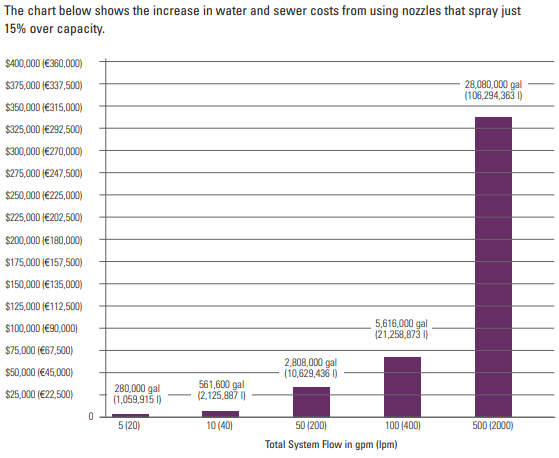

Over time, nozzles can wear out due to erosion, corrosion, or blockages, which can alter spray patterns and reduce effectiveness. This can result in uneven coverage, increased use of chemicals or water, and higher operational costs. For example, a nozzle with a worn orifice may produce larger droplets or an irregular spray pattern, leading to inefficient application of materials and potential product wastage. See the chart below for an example of how spraying at 15% over capacity could increase water waste and sewer costs. And keep in mind that in most cases, spraying just 15% over capacity would not be noticeable without measuring flow. An increase in flow rate can result in:

- • Waste of the solution being sprayed

- • Increased pump energy use

- • Increased sewer costs

- • Increased wastewater treatment costs

- • Quality problems caused by inconsistent application of the solution being sprayed

Savings With Longer Nozzle Life

Investing time in regular nozzle maintenance can lead to significant cost savings. Keeping nozzles in good condition reduces the frequency of replacements and minimizes downtime of repairs. Well-maintained nozzles also operate more efficiently, reducing the amount of energy and resources needed for spraying operations. This lowers direct costs and contributes to a more sustainable and environmentally friendly operation.

Additionally, you may want to consider changing the material of the nozzles that you currently use. If you notice that you are constantly having to change your nozzles, then you may want to consider using a harder nozzle material. Click here to read about how a pet food manufacturer saved $8,000 per month using a longer-lasting nozzle. The chart below is a list of materials and their abrasion resistance ratios. If you would like to talk more about selecting the right nozzle material for your application, contact one of our Spray Experts.

Prevent Downtime and Equipment Damage

Neglecting nozzle maintenance can lead to more severe problems that impact the entire spray system. Clogged or damaged nozzles can cause backpressure, which can strain pumps and other components, leading to potential equipment failure. By incorporating a routine nozzle maintenance schedule, you can identify and address issues early, preventing costly repairs and unexpected downtime.

Ensuring Safety and Compliance

In many industrial applications, maintaining nozzles is not just about efficiency and cost savings—it’s also a matter of safety and regulatory compliance. Properly functioning nozzles ensure that chemicals are applied evenly and at the correct dosage, reducing the risk of over-application or environmental contamination. This is particularly important in industries where precise application is critical, such as applying pesticides or food processing. For example, pending legislation (The PURR Act) is expected to enforce pet food manufacturing to become stricter for manufacturers and adhere to human grade standards. This puts more emphasis on manufacturers to be consistent in their operations to produce a uniform product and comply with health standards.

A routine nozzle maintenance program can ensure that your spray systems operate smoothly, efficiently, and safely, delivering optimal performance in every application.

Common Nozzle Problems and Solutions

Understanding common problems and their solutions can help you maintain your nozzles more effectively. Here are some typical issues and how to address them:

Wear and Erosion

Wear and erosion can lead to increased flow rates and irregular spray patterns. Regular inspection and timely replacement of worn nozzles can prevent these issues. Using nozzles made from materials resistant to wear and erosion can also help. Learn more about nozzle wear and how to manage it.

Corrosion

The chemical action of the sprayed fluid can break the nozzle material down over time. The effects can be similar to those of erosion and wear: increased flow and poor spray patterns. This can damage the nozzle orifice and affect spray performance. To prevent corrosion, use nozzles made from corrosion-resistant materials such as ceramic or ruby and clean them regularly.

Blockages

Blockages occur when debris, dirt, or mineral deposits accumulate inside the nozzle orifice, disrupting the spray pattern and reducing efficiency. Cleaning nozzles with a soft brush and a non-corrosive solution removes build-up of debris. For stubborn blockages, soaking the nozzle in a vinegar-water solution can help loosen the material. Installing line strainers or filters in your system can significantly reduce the likelihood of blockages by preventing larger particles from entering the nozzle.

What Are Signs Your Nozzle Needs Maintenance?

Identifying when your nozzle requires maintenance is essential to prevent further issues and ensure optimal performance. Here are some common signs that indicate your nozzle might need attention:

Irregular Spray Patterns

One of the most common signs of a worn or clogged nozzle is an irregular spray pattern. However, detecting irregular spray patterns can be difficult using your eyes. See the image below to see a good and a worn spray tip pattern and how hard it can be to differentiate from the two.

Each type of nozzle produces a specific spray pattern, whether it's a flat fan, full cone, or hollow cone. Deviations from the expected pattern can indicate wear or blockage. For example, a flat fan nozzle should produce a uniform spray, but wear can cause a heavy flow in the center and reduced coverage on the edges as shown in the image above. as shown in the image above.

Increased Flow Rates

An increase in the flow rate is another sign of nozzle wear. As the nozzle orifice enlarges, more liquid will pass through, which can lead to costly over-application of chemistry or water. Higher flow rates may also cause an increase in drop size which can cause problems in some applications. Remember that in most cases, a gradual increase in flow will not be noticeable, so regularly monitoring flow rate can help detect this issue early.

Physical Damage to the Nozzle

Physical inspection of the nozzle can reveal visible damage, such as cracks, chips, scratching or abrasions. Even small imperfections can significantly impact spray performance. Regularly inspecting your nozzles for physical damage can help you catch problems before they lead to more serious issues.

Nozzle Maintenance Tips

Clean Your Nozzles

Proper cleaning is a crucial aspect of nozzle maintenance. Here’s how to clean your nozzles effectively:

Materials and Tools

Choosing the correct materials and tools for cleaning your nozzles is essential to avoid damaging them. Use tools that are softer than the nozzle material to prevent scratches and abrasions.

- • Soft-Bristle Brushes: For both metal and plastic nozzles, use brushes with soft bristles. Avoid stiff or abrasive brushes that can scratch the nozzle surface.

- • Non-Corrosive Cleaning Solutions: Soaking nozzles in a solution of vinegar and water can help loosen debris without causing corrosion. This method is particularly useful for nozzles with small orifices.

Basic Cleaning Steps:

- • Gently brush the nozzle with a soft-bristle brush to remove loose debris.

- • For clogged nozzles, use a toothpick or compressed air to dislodge the obstruction. Always work the clog out in the opposite direction of the spray to avoid pushing debris further into the nozzle.

- • Soak the nozzle in a non-corrosive solution, such as vinegar and water, to dissolve any remaining debris. For a full instructional video on how to clean your nozzles, click the link below.

Establishing a Regular Nozzle Inspection Schedule

Regular inspection of your spray nozzles is essential for maintaining performance and extending their lifespan. It helps you catch problems early which can prevent costly downtime and ensure consistent spray quality. Here are some steps to establish a nozzle inspection schedule.

Determine Inspection Frequency

The frequency of inspections should be tailored to the specific needs of your application. High-use nozzles, or those in demanding environments, require more frequent inspections (weekly or bi-weekly), while nozzles in less harsh conditions can be inspected monthly or quarterly. Consulting with a Spray Expert to determine this can help.

Create an Inspection Checklist

A comprehensive checklist ensures thorough examination of all critical aspects of the nozzle:

- • Visual Inspection: Look for physical damage, signs of corrosion, and wear on the nozzle body and orifice.

- • Spray Pattern Evaluation: Compare the spray pattern to the original specifications to detect any irregularities.

- • Flow Rate Measurement: Measure the flow rate to ensure it matches the nozzle’s specifications, as deviations can indicate wear or erosion.

- • Clog Detection: Check for blockages and clear them using appropriate tools, such as compressed air or a soft brush.

Record Keeping and Documentation

Maintaining detailed records of each inspection is vital for tracking nozzle performance over time. Document the inspection date, nozzle condition, performed actions, and performance metrics. This helps identify recurring issues and aids in maintenance planning.

Establishing Maintenance Intervals

Based on inspection findings, establish maintenance intervals specific to your operation’s needs. Regular maintenance should include:

- • Cleaning: Implement a routine cleaning schedule using appropriate tools and non-corrosive solutions.

- • Repairs: Address minor issues immediately to prevent them from becoming major problems. Replace worn or damaged nozzles as needed.

For a more detailed outline of a maintenance checklist, click here to view our manual.

Conclusion

Regular nozzle maintenance is essential for optimal performance and cost efficiency. Following these tips and establishing a routine maintenance schedule, you can ensure your industrial spray nozzles remain in top condition. Consulting with Spray Experts can provide valuable insights and help develop a customized maintenance schedule, ensuring your nozzles remain in top condition.

For more information on nozzle maintenance, visit spray.com or contact our spray specialists.