Tag: Automatic Nozzles

17

Jul 24

Spraying Systems Co. is proud to announce our collaboration with the University of Wisconsin – Stevens Point Paper Science and Chemical Engineering program! UWSP is now equipped with our state-of-the-art showers featuring HP cleaning nozzles, fan cleaning and lubrication nozzles, trimming nozzles, air atomizing coating guns and nozzles, and an automatic tank cleaning device. This equipment provides UWSP with cutting-edge tools to enhance the Pilot Paper machine's performance, addressing fabric cleaning, precise trim cuts, automated tank cleaning, and precise coatings application post-drying.

Read More +Maintaining your spray nozzles is crucial for ensuring optimal performance and longevity in industrial applications. Proper nozzle maintenance enhances efficiency and reduces costs by preventing premature wear and tear. Here we will explore essential nozzle maintenance practices, including nozzle cleaning tips and some common issues with nozzles. We aim to provide practical insights to help you maintain your spray nozzles effectively, ensuring they operate at their best for as long as possible.

Read More +At Spraying Systems Co., we understand the challenges faced by the pet food industry in maintaining quality, productivity, and cost-effectiveness. That's why we're excited to discuss the potential impact of the Pet Food Uniform Regulatory Reform (PURR) Act of 2024 on the industry and how our spray technology solutions can contribute to its objectives.

Read More +World Water Day is a powerful reminder of water's critical role in our lives and the need to manage this invaluable resource with care. At Spraying Systems Co., our commitment to reducing our customers' environmental footprint has been a cornerstone since our inception over 85 years ago. Our extensive product line, developed through decades of experience, is designed to conserve water across many applications, demonstrating our dedication to sustainability.

Read More +15

Jan 24

In this blog post, learn key factors for selecting the right nozzle, impacting efficiency and cost savings. Discover how spray patterns, flow rates, and other features match different needs. The post also offers tips on maintenance and upgrades, highlighting a case where a simple nozzle change saved a company $10M. Ideal for anyone looking to optimize their spray processes, this guide emphasizes expert consultation for best results.

Read More +20

Nov 23

Nozzle clogging is a common yet inconvenient problem, affecting operational efficiency and product quality. Learn more about the primary causes of nozzle clogging and five actionable strategies to mitigate this issue.

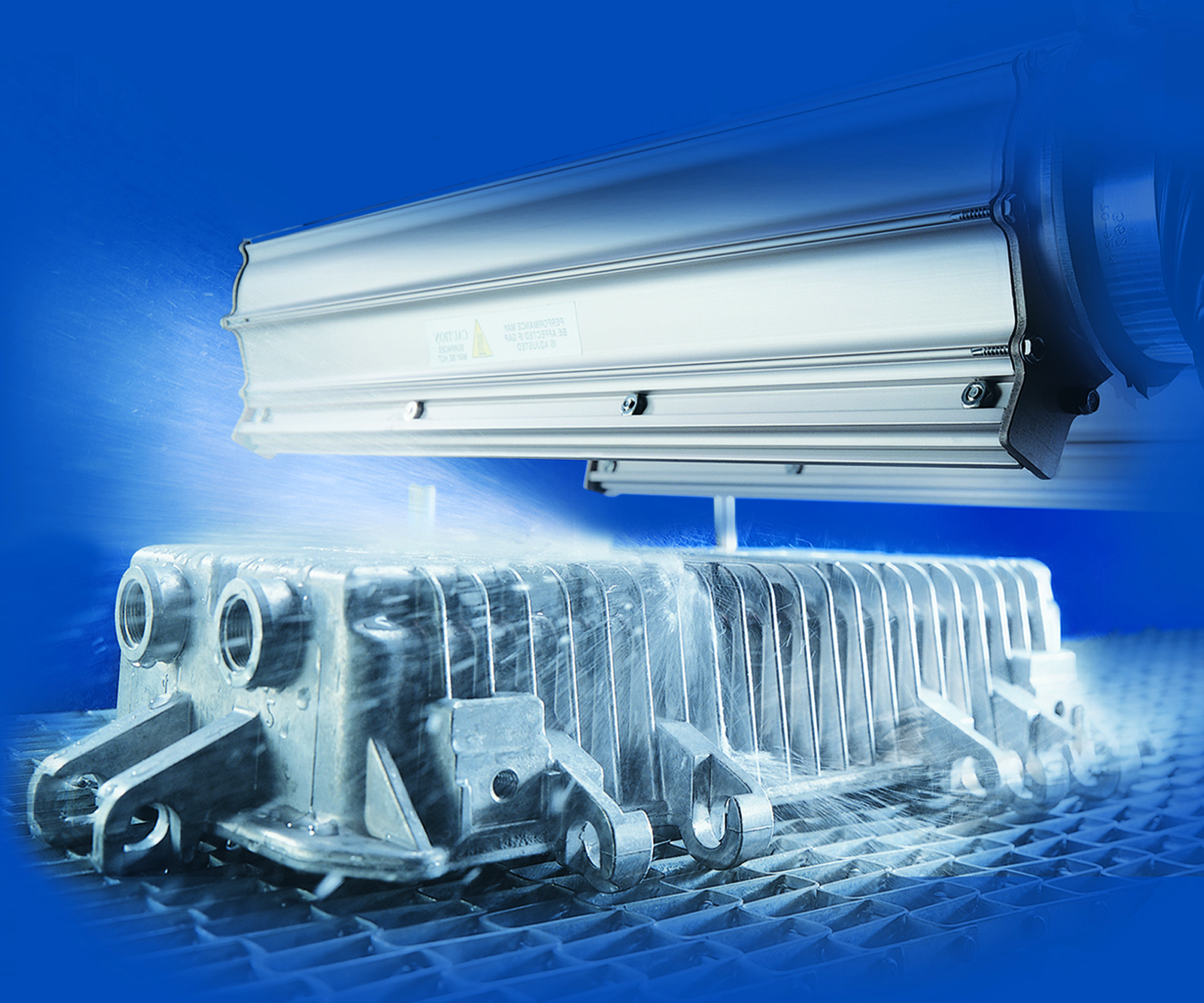

Read More +This article covers the substantial cost savings and operational enhancements achievable in industrial plants by optimizing or substituting compressed air usage in drying and blow-off operations. It emphasizes the advantages of implementing WindJet® air products, draws comparisons with alternative techniques, and shares several success stories.

Read More +Nozzle wear is a critical, often overlooked issue in manufacturing that, when ignored, can lead to substantial implications for both production costs and product quality. This article delves deeper into the importance of detecting and managing nozzle wear, providing a comprehensive guide for engineers and manufacturers.

Read More +