Tag: Tank Cleaning

17

Jul 24

Spraying Systems Co. is proud to announce our collaboration with the University of Wisconsin – Stevens Point Paper Science and Chemical Engineering program! UWSP is now equipped with our state-of-the-art showers featuring HP cleaning nozzles, fan cleaning and lubrication nozzles, trimming nozzles, air atomizing coating guns and nozzles, and an automatic tank cleaning device. This equipment provides UWSP with cutting-edge tools to enhance the Pilot Paper machine's performance, addressing fabric cleaning, precise trim cuts, automated tank cleaning, and precise coatings application post-drying.

Read More +The shift towards automated tank cleaning is becoming increasingly critical in today's industrial landscape. This blog post offers an insightful overview of how automation not only surpasses manual cleaning in efficiency and effectiveness but also aligns with the pressing need for sustainability and safety in operations. We'll discuss the tangible benefits and operational improvements that come with automated cleaning technologies, urging professionals to consider this transition.

Read More +When it comes to maintaining the productivity of your processing, mixing and storage tanks, choosing the right cleaning equipment is critical. This guide will help you understand the key factors that affect cleaning efficiency and how to select the right tank cleaning system for your needs.

Read More +At Spraying Systems Co., we understand the challenges faced by the pet food industry in maintaining quality, productivity, and cost-effectiveness. That's why we're excited to discuss the potential impact of the Pet Food Uniform Regulatory Reform (PURR) Act of 2024 on the industry and how our spray technology solutions can contribute to its objectives.

Read More +World Water Day is a powerful reminder of water's critical role in our lives and the need to manage this invaluable resource with care. At Spraying Systems Co., our commitment to reducing our customers' environmental footprint has been a cornerstone since our inception over 85 years ago. Our extensive product line, developed through decades of experience, is designed to conserve water across many applications, demonstrating our dedication to sustainability.

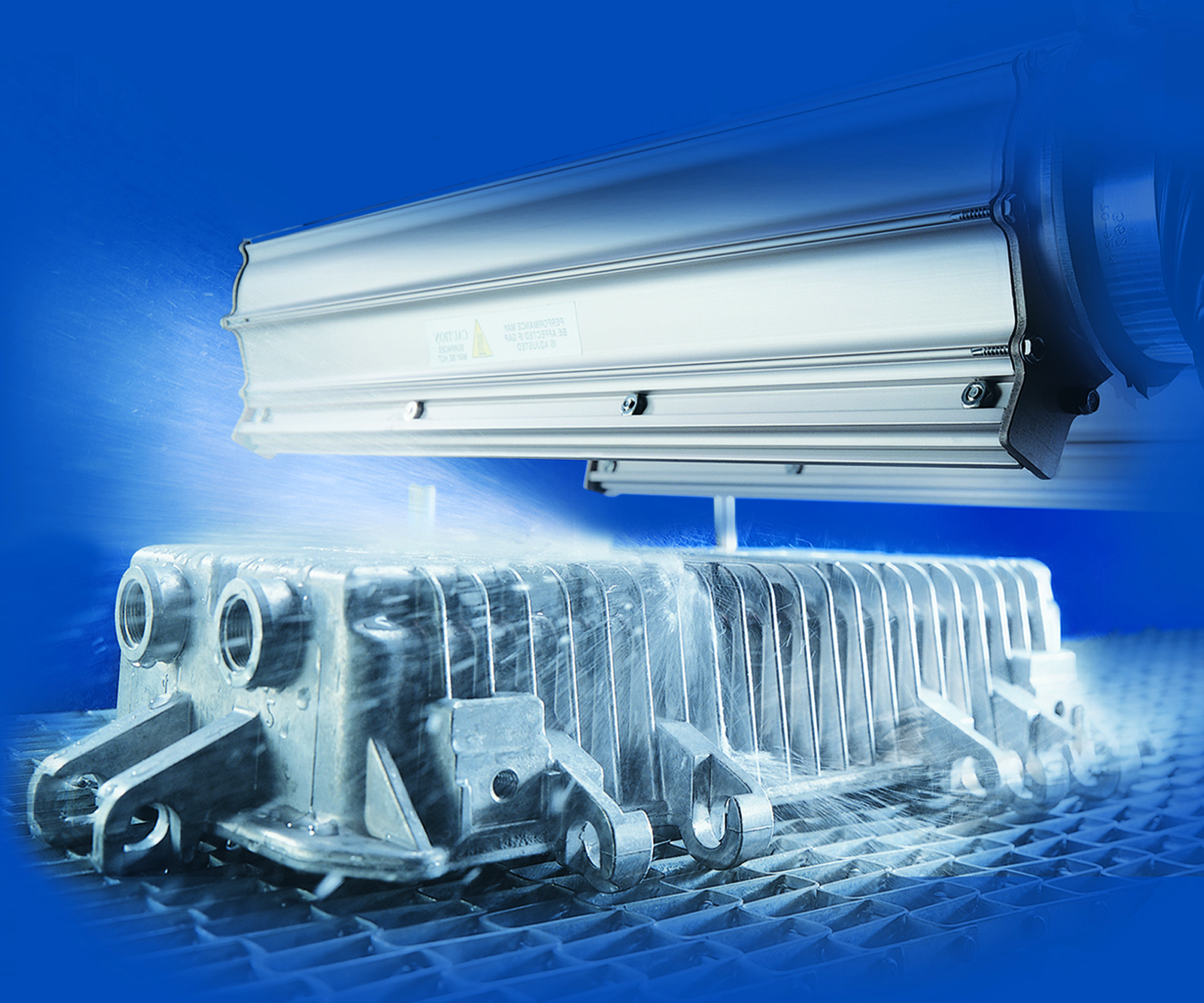

Read More +This article covers the substantial cost savings and operational enhancements achievable in industrial plants by optimizing or substituting compressed air usage in drying and blow-off operations. It emphasizes the advantages of implementing WindJet® air products, draws comparisons with alternative techniques, and shares several success stories.

Read More +