Shiploader Spray Bar

29

May 22

Spray technology plays an integral role in improving the safety and efficiency of mining operations in Australia, and this includes the spray bars that are used on shiploaders. We design and fabricate them right here in Australia with our team of experienced engineers.

This spray bar controls the dust as it comes off the shipload conveyor boom and moves onto the ore carrier.

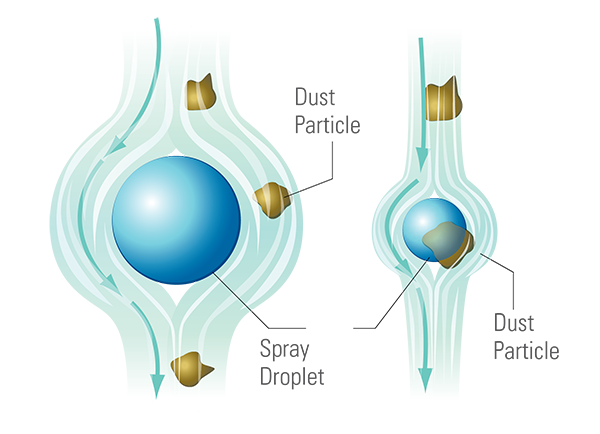

At Spraying Systems, we use either a FullJet Nozzle or a WhirlJet Nozzle, with a hallow cone, for shiploader spray bars. Our Spray expert has chosen the WhirlJet Nozzles in this instance as it produces a smaller water droplet than the FullJet Nozzle. This will be more effective at controlling the airborne dust for our customer in this scenario.

For mining applications such as this, we also recommended using a valve assembly with feedback to monitor the operation status of the nozzles. This option allows for an auto-purge cleaning of the strainer.

As you can see in the video, the required pressure could be pretty high, around 10-12 Bar, with a minimum of 7 bar.

If you would like to know more about this or any dust control solutions that Spraying Systems can provide, contact our team or read our comprehensive Dust Control Bulletin below.