Spraying Systems Reduces Bakeries Energy Consumption by 86% On Line

Through on site spray analysis, a large bakery in Australia was able to reduce energy consumption by 86%

31

Aug 22

A large bakery in Australia was using several compressed air nozzles in order to both remove remaining product residue and to dry the trays. This process was ineffective and required an additional heater element to properly dry the tray. The added ongoing energy and maintenance costs to the process.

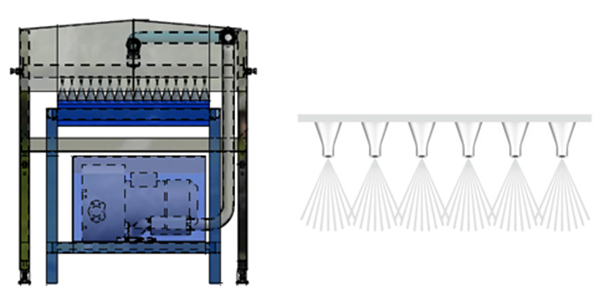

After a free site audit, our spray experts designed a blower package with a hood enclosure an air cannon manifold. This replaced the compressed air nozzles allowed the customer to remove the heating element, resulting in efficiency and safety improvements.

RESULTS:

- Approx. 86% energy reduction compared to compressed air nozzles

- Eliminated the need of inline heater from existing line for drying the trays

- Custom built solution provides consistency and effective outcome for the application

Air Cannon Manifolds are designed to give you superior air impact and coverage. The uniquely designed orifices allow the air to cut through to surfaces further from the manifolds than is possible with continuous slot air knives. Air Cannon Manifolds are custom built to suit your business needs, and can range from 100mm to over 10m